AGC (AGC Inc., Headquarters: Tokyo; President: Yoshinori Hirai), a world-leading manufacturer of glass, chemicals and other high-tech materials, has established a joint research program within the Graduate School of Engineering at the University of Tokyo in 2015 to conduct collaborative research aimed at creating cutting-edge glass technologies. Recently, a research team led by Lecturer Yusuke Ito, and Project Research Associate Yanming Zhang from the University of Tokyo in collaboration with a research group from AGC, have invented a new technique*1 that enables laser processing of transparent materials such as glass at a speed one million times faster than conventional methods. This achievement was published online*2 in the US scientific journal “Science Advances” on June 11, 2025 (local time).

In recent years, the amount of information processing has increased with the spread of generative AI, and faster and more power-efficient semiconductors are now required. As a result, there is a growing trend toward using glass substrates as mounting substrates for semiconductor chips, which offer excellent rigidity and flatness.

Currently, glass substrates are mainly processed by laser ablation*3 or laser modification and etching processes*4. However, the former is slow in processing time, while the latter has large environmental impact, such as waste liquid disposal.

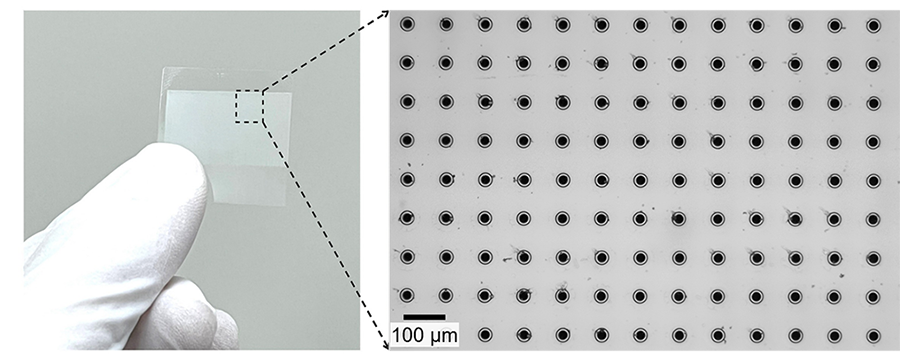

In this joint research, by irradiating two types of lasers with different pulse widths simultaneously and from oblique directions to the glass surface, the team succeeded in increasing the processing speed by a million times compared to laser ablation processing. This method, which enables high-speed processing of glass substrates using only lasers, is more efficient and has a lower environmental impact than existing processing methods and is expected to be put to practical use in the semiconductor field in the future.

Under the Group philosophy “Look Beyond”, the AGC Group has made it our Purpose to make people’s lives better around the world by delivering our unique materials and solutions. We will continue to promote open innovation and accelerate the speed of development by integrating internal and external technologies to create new value for our customers and society.

Reference

Press release from the University of Tokyo on this subject

https://www.t.u-tokyo.ac.jp/en/press/pr2025-06-12-001

Notes

|

*1 |

Joint patent application has been filed by the University of Tokyo and AGC |

|

*2 |

Papers Journal: Science Advances Title: Ultra-high-speed laser drilling of transparent materials via transient electronic excitation DOI: 10.1126/sciadv.adv4436 URL: https://www.science.org/doi/10.1126/sciadv.adv4436 Authors: Graduate School of Engineering, the University of Tokyo Yusuke Ito, Yanming Zhang, Takumi Koike, Reina Yoshizaki, Guoqi Ren, Sota Kiriake, Ryota Hasegawa, Keisuke Nagato, Naohiko Sugita AGC Inc. Akihiro Shibata, Ikuo Nagasawa |

|

*3 |

Laser ablation processing: A processing technique in which the surface of a material is vaporized or removed instantaneously by irradiating it with a laser beam. The use of high-energy laser enables precise micro processing and thin-film formation. |

|

*4 |

Laser modification and etching process: Technology that achieves micro processing by using a laser to change the properties of materials, followed by an etching process. |